Типы цепочек поставок: Модели, преимущества и интеграция логистики

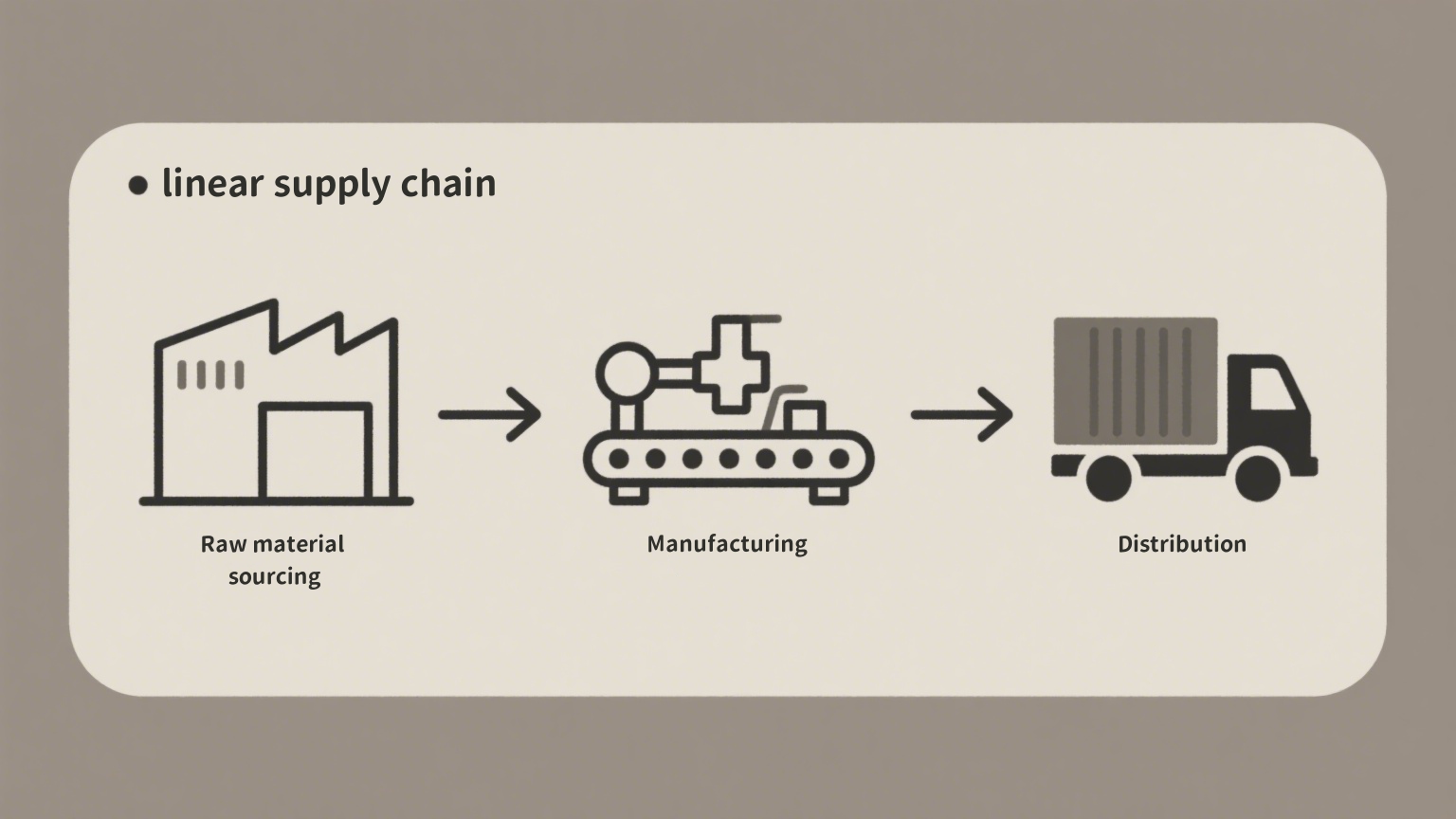

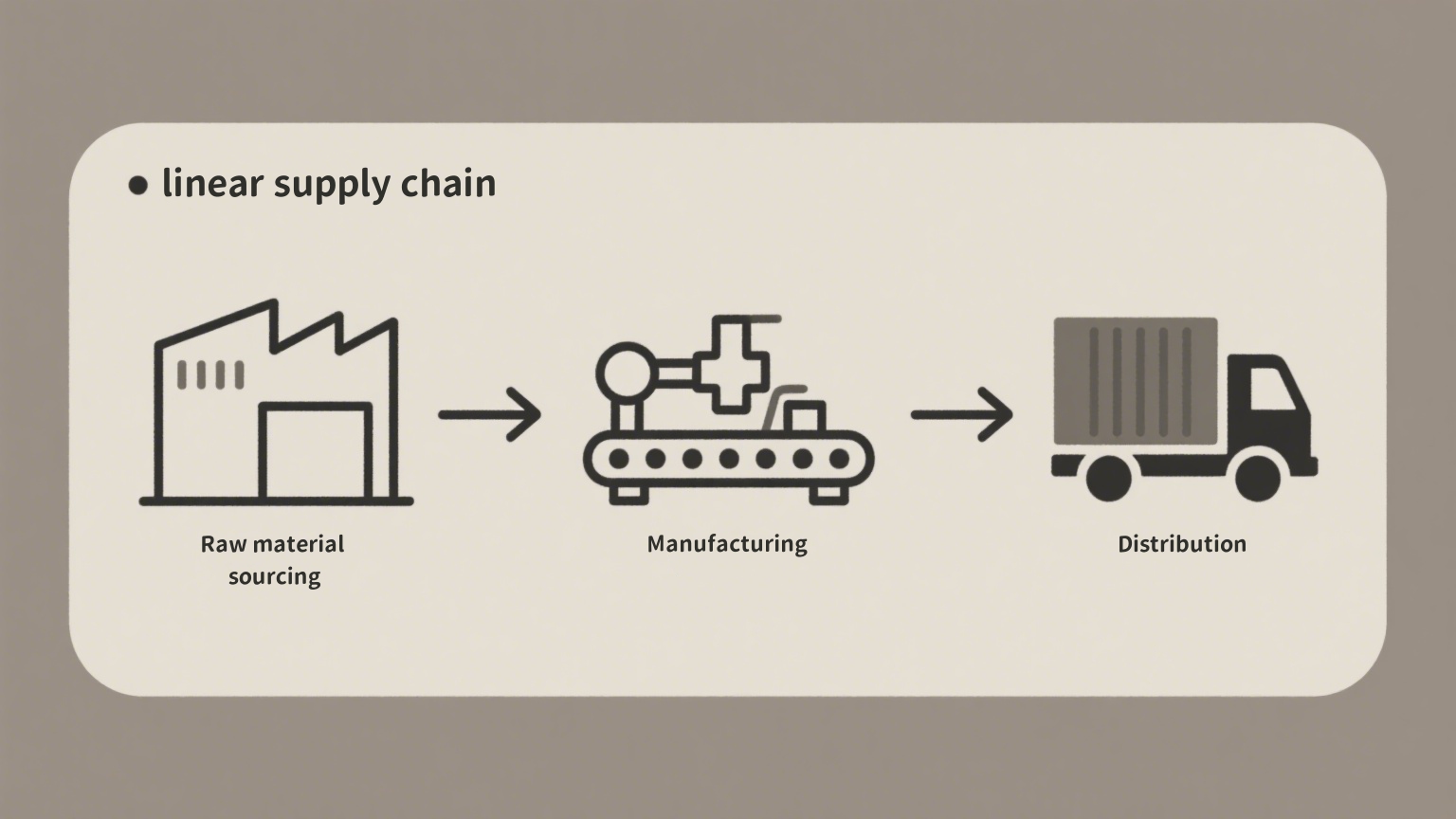

Цепочка поставок — это целая сеть организаций, людей, видов деятельности, информации и ресурсов, участвующих в перемещении товара или услуги от места происхождения до конечного потребителя. На практике цепочка поставок обычно включает три этапа: поставлять (поиск сырья), производство (преобразование материалов в продукты) и распределение (доставка готовой продукции). Современный глобальные сети цепочек поставок Может охватывать несколько стран и включать множество уровней поставщиков, что делает их чрезвычайно сложными. Эффективная координация на всех этих этапах крайне важна, поэтому эффективное управление цепочкой поставок жизненно важно для бизнеса. В следующем разделе объясняется, почему эффективное управление цепочкой поставок существенно влияет на результаты деятельности компании.

На рисунке выше представлена базовая корпоративная цепочка поставок. Она показывает, как материалы поступают от поставщиков верхнего уровня через процессы закупок, производства и продаж компании, достигая в конечном итоге потребителей. Этот поток отражает типичные этапы цепочки поставок, описанные выше. В терминах цепочки поставок движение от поставщиков к производителям называется «восходящим потоком», а путь от заводов к конечным потребителям — «нисходящим потоком». Планируя эти потоки, компании могут оптимизировать управление запасами, транспортировку и планирование спроса на протяжении всей своей цепочки поставок.

Почему управление цепочками поставок имеет значение

Эффективное управление цепочкой поставок напрямую влияет на прибыль компании и удовлетворенность клиентов. Ключевые преимущества включают:

Стоимость и рентабельность: На деятельность в цепочке поставок может приходиться значительная доля выручки, часто 10–20%. Устранение потерь и оптимизация процессов в цепочке поставок снижают эксплуатационные расходы и увеличивают рентабельность.

Денежный поток: Улучшенное планирование и координация позволяют избежать избыточных запасов или срочных поставок, высвобождая денежные средства. Другими словами, эффективное управление цепочкой поставок сокращает оборотный капитал, замороженный в логистике.

Конкурентное преимущество: Быстрое и надежное выполнение заказов может стать отличительной чертой компании. Как отмечает NetSuite, клиенты теперь ожидают выполнения заказов на следующий день или доставка в тот же день, поэтому высокоэффективная цепочка поставок обеспечивает реальное конкурентное преимущество.

Управление рисками: Цепочка поставок является основным источником риска (задержки из-за погоды, резкие скачки спроса и т. д.). Проактивное планирование цепочки поставок и прозрачность позволяют минимизировать сбои, которые могут нанести ущерб нашей репутации.

Рост доходов: Когда спрос резко растёт, гибкая цепочка поставок позволяет компании быстро реагировать и увеличивать продажи. Хорошо отлаженная цепочка помогает компаниям наращивать производство и скорость поставок, что приводит к росту выручки.

Подводя итог, можно сказать, что каждый доллар, сэкономленный за счёт оптимизации цепочки поставок, напрямую увеличивает прибыльность, а улучшение обслуживания (ускоренная отгрузка, своевременная доставка) увеличивает долю рынка. Именно поэтому стратегические управление цепочками поставок (SCM) является приоритетной задачей для современных компаний. Например, SCM определяется как управление всеми этапами цепочки поставок компании — от поиска поставщиков до доставки клиентам — часто с использованием интегрированных ERP-систем.

Общие модели цепочки поставок

Компании обычно выстраивают свои цепочки поставок, ориентируясь на ключевые приоритеты — в основном, на экономическую эффективность и оперативность. Шесть стандартных модели цепочки поставок часто цитируются:

| Модель цепочки поставок | Фокус | Лучше всего подходит для случаев использования |

|---|

| Эффективный | Низкие затраты и комплексная эффективность | Товарные продукты со стабильным спросом (например, рис, топливо) |

| Быстрый | Скорость выхода на рынок | Товары с коротким жизненным циклом или товары, ориентированные на тренды (например, мода, электроника) |

| Непрерывный поток | Высокий уровень обслуживания клиентов, оборачиваемость запасов | Отрасли с очень стабильным спросом и предложением (например, основные потребительские товары) |

| Гибкий | Гибкость и быстрое реагирование | Индивидуально изготовленные или непредсказуемые продукты (например, индивидуальное оборудование) |

| Индивидуально настроенный | Разнообразие продукции и индивидуализация | Компании, предлагающие множество версий продукции (например, автомобильные детали смешанного типа) |

| Гибкий | Управление всплесками спроса | Сезонные или чрезвычайные ситуации, требующие быстрого масштабирования (например, гуманитарная помощь) |

Эти модели подчеркивают компромиссы: цепочки, ориентированные на стоимость (Эффективный, Быстрый, Непрерывный) полагаются на точные прогнозы и ограниченные запасы, в то время как цепочки, ориентированные на отзывчивость (Agile, Custom, Flexible) делают акцент на скорости и гибкости для удовлетворения меняющегося спроса. Например, эффективная модель цепочки поставок идеально подходит для низкорентабельных товаров и требует точности прогнозов, тогда как гибкая модель предназначена для высокоиндивидуализированных продуктов, производимых небольшими партиями.

Стратегии цепочки поставок: бережливые и гибкие

Помимо этих моделей, компании часто применяют конкретные стратегии, основанные на рыночных потребностях. бережливая цепочка поставок фокусируется на эффективности и сокращении отходов (вспомните производственную систему Toyota). Она использует такие методы, как система «точно вовремя», чтобы минимизировать излишки запасов и исключить любые процессы, не добавляющие ценности для клиента. На стабильных, предсказуемых рынках бережливые (эффективные) цепочки максимизируют прибыльность.

В отличие от этого, гибкая цепочка поставок Скорость и гибкость — приоритет для реагирования на меняющийся спрос. Гибкие цепочки поставок используют резервные запасы и быструю транспортировку для быстрой адаптации. Как поясняет Procurify, «бережливая цепочка поставок фокусируется на эффективности, снижении затрат и минимизации отходов», тогда как «гибкая цепочка поставок делает акцент на гибкости и реагировании» на непредсказуемый спрос.

Модель Фишера Гарварда связывает это с типами продуктов: функциональные продукты (со стабильным спросом и длительным жизненным циклом) подходят для экономичных/эффективных цепочек поставок, в то время как инновационные продукты (непредсказуемый спрос, короткие жизненные циклы) требуют гибких, отзывчивых цепочек поставок. Например, для обычного потребительского товара (функционального) лучше всего подходит цепочка поставок, ориентированная на эффективность, тогда как для модного гаджета (инновационного) нужна гибкая цепочка поставок с короткими сроками поставки. Многие компании сейчас используют гибридные стратегии, сочетая гибкие и рациональные методы (часто реализуемые с помощью технологий) для балансировки затрат и обслуживания.

Специализированные категории цепочки поставок

Цепочки поставок также можно классифицировать по области применения или целевому назначению. Например, прямая цепочка поставок представляет собой простой линейный поток от производителя к оптовому продавцу, а затем к розничному продавцу. Расширенная цепочка поставок идёт дальше, связывая поставщиков поставщиков и клиентов клиентов, обеспечивая полную сквозную прозрачность.

Другие важные типы включают в себя:

Глобальная цепочка поставок: Охватывает несколько стран и видов транспорта. По данным отраслевых источников, современные глобальные цепочки поставок «чрезвычайно сложны» из-за интернационализации. Управление глобальной цепочкой поставок подразумевает необходимость учитывать различные нормативные акты, валютные и таможенные правила, а также более длительные сроки поставки.

Экологичная (устойчивая) цепочка поставок: Включает в себя принципы экологической и социальной ответственности. Компании, использующие экологичные методы управления цепочками поставок, стремятся сократить отходы, потребление энергии и выбросы на всех этапах закупок и логистики для достижения целей ESG.

Цифровая цепочка поставок: Использует технологии (Интернет вещей, искусственный интеллект, большие данные) для связи всех партнеров. Цифровая цепочка обеспечивает отслеживание запасов и поставок в режиме реального времени, что позволяет автоматически принимать решения и оптимизировать процессы. Например, цифровые платформы могут автоматически дозаказывать товары и выбирать оптимальных перевозчиков на основе текущих прогнозов спроса.

Гибкая и устойчивая цепочка поставок: Этот тип, который иногда выделяют отдельно, делает акцент на адаптивности и быстром восстановлении после сбоев. Он пересекается с гибкой стратегией, но часто включает в себя резервных поставщиков и дополнительные ресурсы для обеспечения устойчивости.

Каждая категория отвечает конкретным потребностям бизнеса – например, компания по производству бытовой электроники может потребоваться высокогибкая и цифровая цепочка поставок, в то время как производитель оптовых химикатов может отдать приоритет эффективной глобальной цепочке.

Как цепочка поставок влияет на логистику

Логистика, включающая транспортировку, складирование и доставку товаров, является важнейшей частью цепочки поставок. Затраты на логистику (транспортные расходы, складирование, оплата труда, упаковка и т. д.) составляют значительную часть общих расходов цепочки поставок. Любое улучшение всей цепочки поставок напрямую влияет на эффективность логистики.

Например, Flowspace отмечает, что расходы на логистику Включают «расходы, понесенные при перемещении продукции от места производства до конечной доставки», включая транспортировку, хранение и обработку. Оптимизируя цепочку поставок, например, консолидируя поставки, оптимизируя места хранения запасов или используя сторонние логистические услуги (3PL) партнера, компании могут сократить эти расходы. NetSuite подчёркивает, что логистика — это часть цепочки поставок, ориентированная на перемещение товаров, а это означает, что эффективное планирование цепочки поставок (например, проектирование сети и планирование спроса) приводит к более быстрой и надёжной доставке и снижению транспортных расходов.

На практике более эффективная координация цепочки поставок приводит к конкретным результатам в логистике: уменьшению дефицита запасов, уменьшению числа экстренных авиаперевозок и повышению эффективности складских операций. Например, благодаря интеграции технологий цепочки поставок (таких как отслеживание в режиме реального времени) компании могут повысить точность поставок и сократить задержки. В конечном счёте, эффективное управление цепочкой поставок улучшает как контроль затрат, так и качество обслуживания в логистике.

Часто задаваемые вопросы (FAQ)

В: В чем разница между цепочкой поставок и логистикой?

A: Цепочка поставок охватывает весь путь продукта от начала до конца, от сырья и производства до доставки конечному потребителю. Логистика является ключевым звеном этой цепочки, занимаясь, в частности, транспортировкой и хранением товаров. Другими словами, логистика — это «часть цепочки поставок, включающая управление складскими и транспортными потоками». Управление цепочкой поставок рассматривает общую картину (закупки, производство, планирование дистрибуции), в то время как управление логистикой фокусируется на эффективном перемещении и хранении запасов.

В: Почему управление цепочками поставок важно для моего бизнеса?

A: Эффективная система управления цепочками поставок напрямую влияет на прибыльность и удовлетворенность клиентов. Оптимизированная цепочка поставок сокращает расходы (уменьшая количество отходов и избыточных запасов), улучшает денежный поток и обеспечивает конкурентные преимущества за счет ускорения поставок. Она также снижает риски (например, связанные с перебоями в работе поставщиков) и позволяет компании быстро масштабироваться при росте спроса. Иными словами, эффективное управление цепочкой поставок может увеличить выручку и сохранить рентабельность.

В: Каковы наиболее распространённые модели или типы цепочек поставок?

A: Существует множество фреймворков. Отраслевые эксперты часто выделяют шесть моделей: эффективную, быструю, непрерывного потока, гибкую, настраиваемую и гибкую (см. таблицу выше). Каждая модель подходит для разных сценариев — например, эффективная цепочка идеально подходит для конкурентоспособных по стоимости товаров, а гибкая — для настраиваемых или непредсказуемых продуктов. Другие классификации включают бережливые, цифровые и экологичные цепочки поставок, а также прямые и расширенные сети, в зависимости от стратегии компании.

В: В чем разница между бережливой и гибкой цепочкой поставок?

A: Бережливая цепочка поставок делает акцент на эффективности затрат и сокращении отходов, используя такие методы, как производство «точно вовремя», для минимизации избыточных запасов. Это наиболее эффективно в условиях стабильного спроса. Гибкая цепочка поставок, напротив, делает акцент на гибкости и реагировании на потребности клиентов. Гибкие цепочки поставок поддерживают резервный запас и используют быструю транспортировку для адаптации к внезапным изменениям. Выбор зависит от продукта и рынка: например, для предсказуемых продуктов часто применяются бережливые методы, в то время как для продуктов с высокой степенью вариативности или индивидуальных заказов требуется гибкий подход.

В: Как сотрудничество с 3PL-поставщиком (сторонним логистическим провайдером) поможет моей цепочке поставок?

A: 3PL-партнёр может стать продолжением цепочки поставок вашей компании. Он выполняет такие задачи, как складирование, выполнение заказов, транспортировка и даже поддержка клиентов. Как показывает один из примеров из отрасли, 3PL-партнёр «управляет всей цепочкой поставок» от вашего имени, обеспечивая ускоренный оборот денежных средств и повышение качества обслуживания. На практике это означает более быструю обработку заказов, лучшую прозрачность отгрузок и зачастую более низкие затраты (поскольку 3PL-партнёры используют масштаб). Такие компании, как DR Trans, предлагают такую экспертизу: становясь вашим виртуальным логистическим отделом, мы решаем сложные задачи по доставке и оптимизируем весь процесс транспортировки.

В: Как DR Trans может решить мои проблемы с доставкой?

A: DR Trans применяет профессиональные методы управления цепочками поставок к потребностям каждого клиента. Выступая вашим логистическим партнером, мы разрабатываем индивидуальные решения – будь то услуги 3PL или гибридные модели – для оптимизации доставки. Например, мы управляем сквозными процессами доставки, что «обеспечивает стабильное взаимодействие с клиентами и ускоряет циклы выполнения заказов». Другими словами, DR Trans применяет проверенные стратегии управления цепочками поставок для вашего бизнеса, обеспечивая надежные международные перевозки, более быструю доставку и более высокую общую эффективность логистики.

IPv6 ПОДДЕРЖИВАЕТСЯ СЕТЬЮ

IPv6 ПОДДЕРЖИВАЕТСЯ СЕТЬЮ